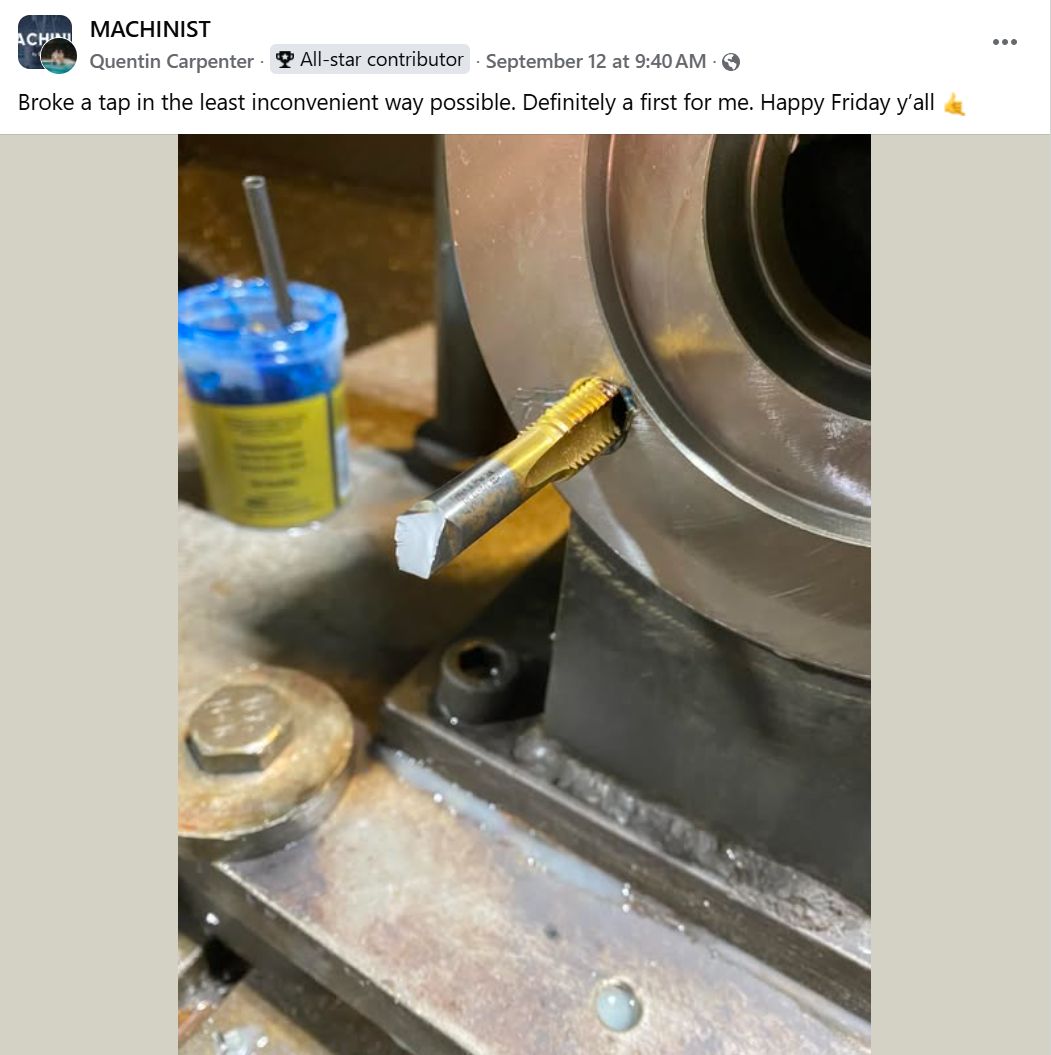

A post from Quentin Carpenter took the machinist world by storm — over 881,000 views and 1,100+ comments — all because of a tap that broke in the best possible way.

“Broke a tap in the least inconvenient way possible. Definitely a first for me. Happy Friday y’all.”

Top comments include:

“If there's a good way to break a tap, that's it”

“You need to go buy a lottery ticket, you’re on a winning streak”

“That's the best way....smack it with a hammer if you want to see the worst way”

“Normally the tap will break in the LAST hole of many, at the DEEPEST position and it will shear off BENEATH the surface, UNREACHABLE and just BEFORE the weekend 😭😭”

👷♂️ hireCNC Featured Jobs

Career Advice

Hey boys and girls, I am making the leap and going to a different company.

The one I work at currently has bad management culture and it's time I go somewhere that I am appreciated better. The work we do here is great because they focus on manufacturing specialty machines so SETUP knowledge is required or at least you need to learn fast.

But I need some advice. The company I am going to does aerospace work and it is pretty repetitive and standardized so I won't be able to use much creativity for setups.

I am okay sacrificing that for the money and extra growth opportunity. However I have worked for an aerospace company in my past and couldn't thrive because I wasnt feeling challenged or stimulated.

In order for me to be successful here, how can I stand out in a more production focused shop? Speed and efficiency?

Thank you for the input.

Top comments include:

“If you wanna stand out in a shop …be the guy who runs quality parts, doesn’t scrap parts or crash machines.

Leave the next shift a clean work area and a machine with fresh tooling that’s putting out in spec parts.”

“Speed and efficiency are not the most important things in aerospace ind. perfect parts are. Tolerance’s are a suggestion. Perfection is the name of the game on dimensions as well as surface finishes. Both correct the first time.” 👍

“Medical and aerospace are where the money is”

“Learn the benefits of applying Statistical Process Control to your work load. Most shops don’t give a shit but ones that have an actual 5S or Kaizen methodology will appreciate you keeping track of things like wear rate if you need to change inserts or cutters altogether. Some places don’t believe in tooling control sheets but in my experience the guys that utilize these types of metrics can remain organized and productive by having a better idea of what to expect esp if a tool breaking can scrap a part.”

“Don’t let the mind numbing work cause you to make mistakes. I work in a job shop now and it’s way better than production. In production settings I find myself getting complacent. It’s to easy. Then I make a stupid mistake. IMO that’s the best way to stand out in a production shop. Do the opposite. Standouts are the ones making the mistakes. If they don’t know your there your doing a great job”